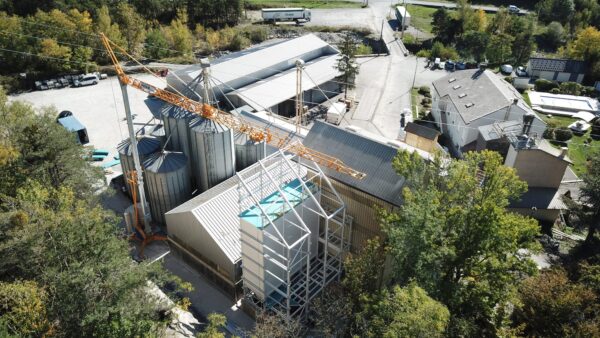

Lindmühle AG

Location: Birmenstorf, Switzerland

Flour: Raw materials and finished products

17.0 m

Project details

The rich history of the Lindmühle goes all the way back to 1363. Today, the Lindmühle is run by the sixth generation of the Lehmann family. TSC supplied and assembled 35 cells here for the storage of raw materials and flour.

Bins

35

Capacity

1.100 m3

Length

15.0 meter

Width

6.5 meter

Highest hygiene standards

Daan van Kempen

Account Manager

In this project, the highest hygiene standards were applied, such as welding off the seams and using stainless steel on the inside. In addition, chances of condensation were minimized even further by leaving space between the flour and raw material cells, which were of course properly sealed.

Want to know more? Mail to d.vankempen@tsc-silos.com or Call with +31683623602

Less

Cost

Waste

More

Result

Sustainability

Procedure

Procedure The regulations of the industry, the properties of the material, the geographical conditions of the construction site, the weather conditions in the region… we leave nothing to chance. We therefore work according to the TSC roadmap. This way, we work efficiently and do not overlook any detail. A solid approach for a solid result.

Questions? Contact us

Customized silo in 7 steps

-

1 Identifying needsIn the first step, we discuss the requirements, capacity needs, external conditions and preconditions. What challenges should we take into account. Result: a programme of requirements; our basis.

-

2 Our proposalOur concrete advice for fulfilling the need. A construction concept, with a tailor-made proposal according to the programme of requirements, complete with a competitive offer and time schedule. Result: The start of our further cooperation.

-

3 CalculationWind pressure, snow load, internal weight, regulations, process flow and other important starting points. Our designers make their calculations with these facts in mind. Result: a reliable construction calculation.

-

4 Detailed engineeringThe new silo plant is now being designed down to the smallest detail and worked out in workshop drawings. All details are discussed together. Resulr: After your approval, we will start production.

-

5 ScheduleReliability is our most important pillar. Our construction planning is therefore well thought out. We take into account the transport route and its obstacles, the (often challenging) situation at the construction site and the local capacity. Result: final planning with delivery date.

-

6 AssemblyLed by a TSC supervisor, our experienced assembly team gets to work. We keep in regular contact about the progress in the meantime. With knowledge of local regulations and the right permits, we work safely and competently. Result: A carefully constructed new silo ready for use!

-

7 Completion and evaluationEvery completion is a moment of celebration. We are happy to evaluate the project together. Of course, because we want to see our work in action, but also to learn from practical experience and fine-tune details where necessary. Result: a long-term partnership.