Hoppers

Always the best-fit design for your project

As the characteristics of all bulk materials are different, the best-fit hopper design will always differ. To ensure the best possible solution for each product, we at TSC have a wide range of hopper designs. And each of these designs is customized based on the clients needs and wishes to ensure the best storage and outflow solution for your project. This involves looking at the best flow, but also the most economical solution.

Classic Hopper

The classic design hopper is well suited to free-flowing grain, pellets and other bulk materials. It is the most straightforward design. It is also suitable for a variety of geometries for connecting devices, such as feeder augers, valves and hatches. It is the basic choice for all kinds of materials.

Products: Grain, Pellets, Granules

Speedwell

For flour and bran-like products, the Speedwell hopper is the best-fit design. With its round shape, large angles and small stiffeners, the design can easily reach angles of 70° to 75°. This ensures mass flow of more difficult-flowing products. In addition, the design is also suitable for the use of vibro-bottoms.

The round shape not only enables steeper hopper angles, but also reduces the need for heavy stiffeners on the hoppers. This means that this design is also often the lightest and most cost-effective design for larger silos.

Products: Flour, bran, minerals

Multi outlet

Storage of some products, requires a different outflow. For example, for products with a short shelf life or where the timing of the process is very important. You do not want some of the good to stay longer in the silo than others. The multi outlet design offers the best guarantees for first-in-first-out handling in your bulk storage. Application asked, among others, by wheat tempering bins.

Products: Grains, Tempering bins

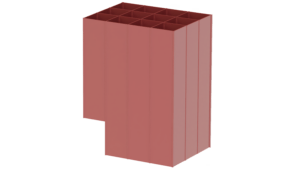

The Bolt

A special variation of the traditional funnel design is our newest creation, ‘The Bolt’. We are proud to say that this design is patented. The Bolt hopper is an innovative design for constructing square silos, fully integrating the hopper with the structural silo column. As a result, this hopper can be installed without on-site welding during assembly. This approach offers several benefits, such as shorter installation time and no damage to paint layers. Installation can also be carried out with minimal impact on plant operations, allowing production to continue uninterrupted. The Bolt is particularly well-suited for handling high-value products like coffee and cocoa.

Products: Coffee, Cocoa

Client design

Some products are special and only the user knows how best to handle their flow. We are specialists in the design of hoppers and we know how to make them strong enough to last a lifetime, no matter what shape they are required to take. So if you know exactly what you want and the standard does not meet your requirements, we are happy to design and build it for you.

Personalized options

- Inspection opening

- Socket for empty sensor with protection roof

- Inspection window

- Poke hole

- Aeration, gas or CO2 socket

- Pressure relief cone

- Expansion step

- Air duct

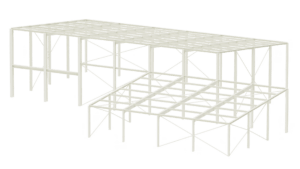

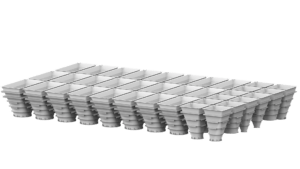

Contrasets

If you have a lot of different products in relatively small volumes but you want to load a bulk trailer quickly, then contrasets are the answer.

A contraset is pretty much a small silo block consisting of various, fairly small compartments. Contraset compartments are connected one by one to the bulk trailer compartments. This means that all the trailer compartments can be loaded at the same time. In the case of traditional loading systems only one or a few compartments are loaded at the same time.

Case studies show that contrasets can cut loading time by up to 80%.

As well as hoppers TSC also supplies bunkers for intermediate storage. Naturally we ensure a seamless fit with the rest of the process.

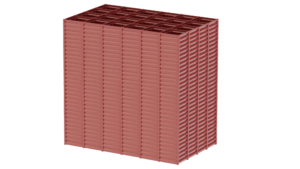

Modular silo system

Our silo system consists of various steel silo parts. We build these up modularly, layer by layer. This system is the best solution for dry and granular bulk goods.

More about silo constructions