Our silo system

Square. That’s what we like at TSC. It is also fully in line with our vision of ‘less is more’. The TSC silo system consists of various steel silo parts. We build these up modularly and layer by layer. Our silo system is the best solution when it comes to dry and granular bulk goods. In many cases, these goods are further processed into various finished products, where square silos play an important role in dosing and storing the finished product. TSC provides the most effective solution for this.

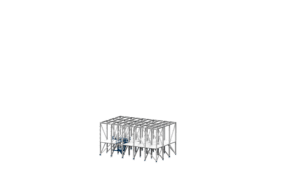

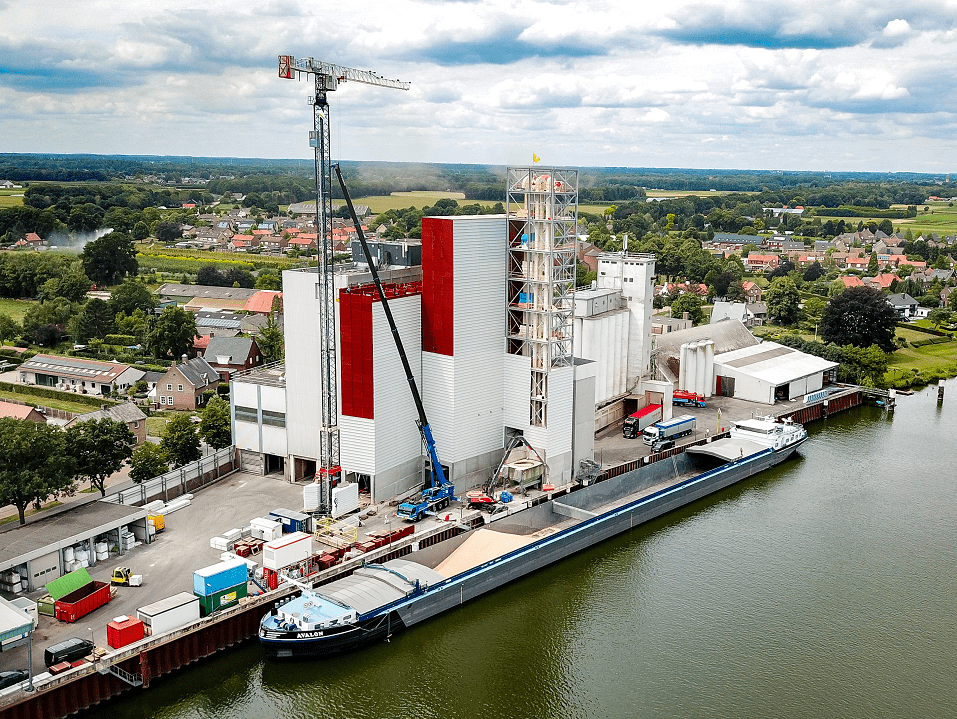

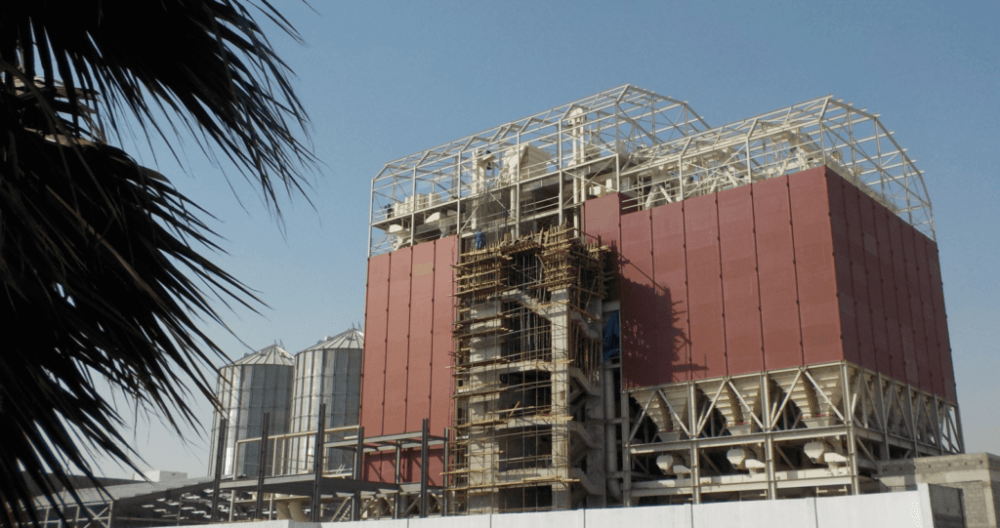

Silos integrated in the building

Our silo system can be a fully integrated and static part of the building. In this way, the available space is optimally used for maximum capacity, and we save a lot of material. One hand reaches the other. More storage at the lowest possible cost. In addition, we can seamlessly integrate related constructions. Think of machine houses, stair towers, and halls. By involving TSC at an early stage, we can guarantee optimal integration and save costs. Less is more comes into its own here.

Benefits of the TSC silo system

- Optimal use of available space

- Different possibilities for the size of the cells

- Square silos integrated into the factory

- Structural part of the building

- Tailer-made

- Durable

- Efficient transport

- 25% extra capacity compared to round

Roof construction

- Representative

- Optional insulation

- Pleasant working climate

- Low noise level for your environment

- Completely customized with optional doors and windows

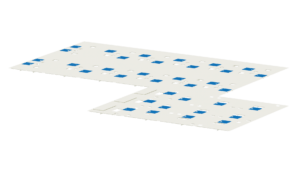

Bin roof

Bin roof- Safe working environment

- Hygienic sealing of the silo bins

- Equipped with a man hatch

- Handrails around the bin roof

- Accessible by stairs

- Machine floor

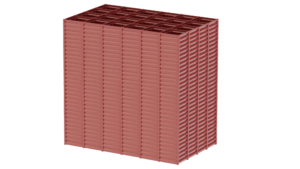

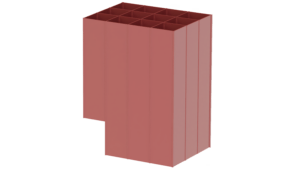

Profiled wall Silo

- Optimum use of volume

- Light construction thanks to single-walled system

- Very strong thanks to profiled walls

- Completely customised, flexible modular construction

- Optional galvanising

- Large capacities per cell possible

Smooth wall silo

- Optimum product discharge

- High degree of flexibility

- Hygienic, low-dust working environment

- No mixing of products between cells

- Fully customised, flexible modular construction

- Very strong as a result of clever design

- Optional coated or stainless-steel walls

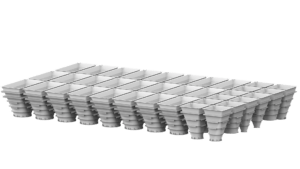

Hoppers

- Smooth overflow from silo to hopper

- Best possible discharge of your product

- Round or square discharge

- Safe and hygienic

- Opening for empty indicators

- Inspection hatches optional

- Seamless fit with downstream process

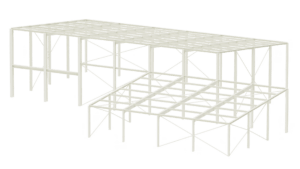

Steel construction

- Made exactly to suit your individual requirements.

- Both support structure and roof structure.

- Safe and robust.

- Includes strength calculations.

- All in accordance with the latest applicable standards.

- Avoid collisions with machinery and/or conveying equipment.

- In-house calculations

The advantages of a TSC Silo system

We know that no project is the same, so neither are our silos. The modular silo system consists of steel silo walls that are installed on site, forming square or rectangular silo cells. We supply silos in custom made dimensions, so that a TSC silo system always meets your needs.

25% more storage capacity

A square silo saves space, simply because the entire surface is used. Square is the right shape for maximum bulk capacity.

Flexibility and traceability

The modular construction with variable cell dimensions makes it possible to store different products and qualities simultaneously and side by side.

Part of the process

Seamlessly integrate square silos into the process. From grinding to pelleting and from dosing to bulk loading, our silos follow the process.

Structural part of the building

Save precious space. There is no need for a separate building for your storage. Floors, stairs and wall cladding can be connected directly to the silo.

Projects

Projects

Every project is tailormade

Whether a smooth wall or a profiled wall is the best choice, or a combination of both, depends on the goods being stored. For each project a different solution is the most suitable. It is also possible to build a cell from one part smooth walls and one part profiled walls. For sensitive finished products, a profiled system may be necessary to reduce the pressure at the bottom of the silo. To improve the product flow towards the hopper, a smooth wall can be used at the bottom. Every project has his own ideal situation.

Fast loading smaller volumes

Do you have many different products in relatively small volumes, but still want to load a bulk trailer quickly? Then contrastsets may be the solution. A contraset is a hopper that is provided with several, relatively small compartments. These small compartments are used as intermediate storage. The contraset compartments connect one on one with the bulk trailer compartments, making it possible to fast load the trailer.