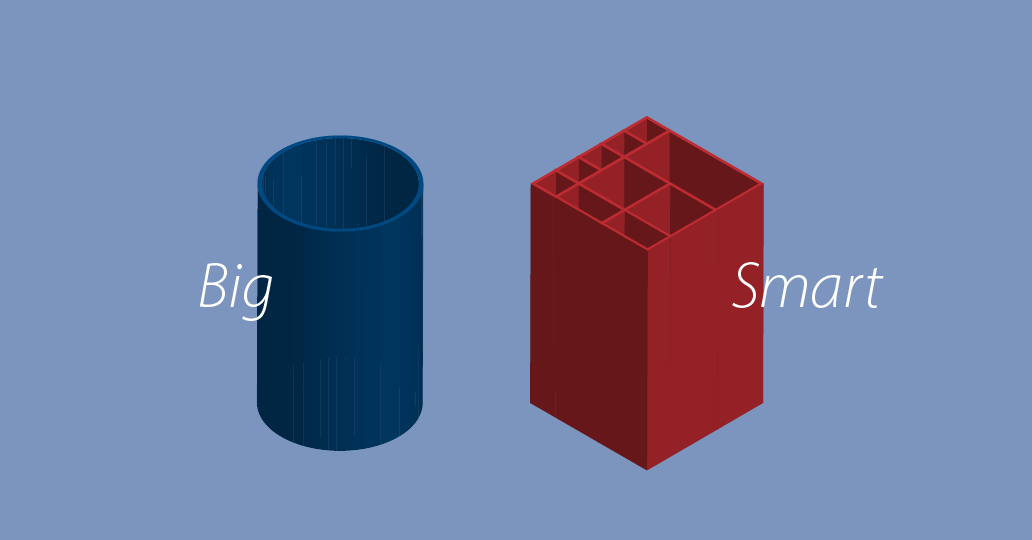

Can thinking Smart beat thinking Big in Storage?

Global feed companies strive to produce and deliver the optimum quality and quantity of product – even in the face of unprecedented supply chain disruption. The feed industry has always relied heavily on storage. Now it was time to ask: is it working for us when we need it most?

This episode includes a multi-dimensional viewpoint from: the feed mill (Klaremelk); the contractor (Silokonsult); and the storage warehouse (Lütolf).

Can thinking Smart beat thinking Big in Storage? (Webazine)

This episode of Triotts FeedForward was recorded on 7 July 2020 with a strong focus on how the global feed & food industry can deliver the optimum quality and quantity of product in the face of unprecedented supply chain disruption. Topics covered included:

• How can ‘smart storage’ help mill owners and operators get more from limited space?

• Balancing the need for ‘buffer storage’ (to mitigate supply chain risk) versus process storage.

• New ideas on improving storage hygiene, consistency and quality – and the value this brings.

• Smart ways to manage long-term revenue versus short-term budgeting for storage.